Airplanes are still covered in fabric?!?

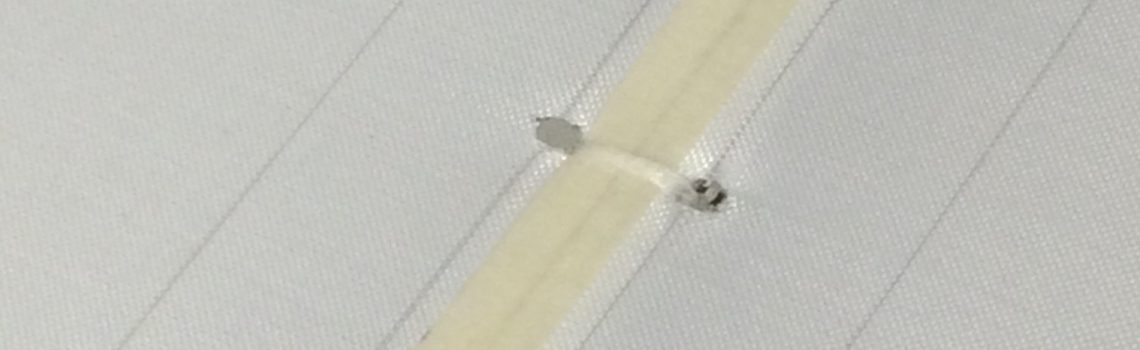

Yes, in fact, there are 34,000+ fabric-covered aircraft registered with the FAA, and “tube-and-fabric” construction continues to be used with new aircraft because of its lightweight and high-strength properties. Fabric coverings are applied to various aircraft structural units, such as control surfaces, fuselages and wings. Fabric is adhered to the aircraft by sewing, riveting, screwing, gluing or tacking to the underlying structural framework, and then tautened (tightened up) in order to provide a streamlined and airtight surface. Even airplanes that are generally classified as “all metal” may have fabric-covered control surfaces. Did you know the P-51 Mustang and B-17 Flying Fortress both utilize fabric-covered control surfaces?

Why does the fabric need to be replaced?

Fabric coverings are more vulnerable to the elements (deterioration associated with UV exposure, tearing from stones kicked up by propeller wash) and lack the durability associated with the aluminum and composite skins used on more modern aircraft, thus giving the fabric a limited lifespan. Removal of old, damaged fabric and replacement with new fabric having a fresh topcoat has been an accepted maintenance procedure for nearly 100 years.

How often do fabric-covered aircraft need to be recovered?

The general recommendation in the aviation community is that all fabric-covered aircraft should be recovered every 20-25 years. Depending on their flying and storage conditions, this timeframe could be reduced to 10 years (e.g. consider a crop-duster that operates from a dirt landing strip), or an airplane that is stored outside and exposed to the elements. Fabric covers themselves have a limited life-span (even the so-called “lifetime” fabrics) due to their exposure to the damaging effects of UV light from sunlight.

The fabric looks OK. What’s the issue?

Nice-looking fabric can hide severely corroded steel tubing of a fuselage longeron or cracks in wooden wing spars or fuselage formers. Moisture is the main enemy of the wood and metal that constitutes the structural framework underneath the fabric cover. A proper recovering job will include an assessment and repairs of the underlying structures to ensure that they are also safe.

In general, what are the steps of recovering an airplane?

There are a few approved processes and product lines, but they all follow the same basic steps: 1) attach the fabric to the airframe, 2) shrink it with heat, 3) apply coatings to seal and protect the fabric from UV rays and 4) paint it to make it look pretty. Each certified fabric system has its own Supplemental Type Certificate (STC), and the systems can not be intermixed.

(Adapted from Ragwing Repair Choices by Mike Gugeler article sidebar from AvWeb Article July 7, 2008. The article originally appeared in Aviation Consumer magazine, Oct. 2007.)